The film canister cannon is an incredibly fun and interesting toy that we found at www.sci-toys.com.

The cannon is simple to make and consists mainly for a film canister and the piezoelectric sparking mechanism from an electric lighter. The fuel can be a spray of any aerosol with alcohol. We prefer Binaca because it seems to deliver the exact right amount of fuel to fire the canister.

Materials

1 electric lighter

1 film can [www.sciencebob.com part no. CAN-300, $13.95 for 30]

1 small piece of wood, at least 1/4" thick

1 black 22 AWG hookup wire, solid, 6" [All Electronics part no. 22RD-25S, $2.30 for 25']

1 red 22 AWG hookup wire, solid, 6" [All Electronics part no. 22BK-25S, $2.30 for 25']

1 Insulation displacement wire connector 26-19 AWG, 2 port [McMaster-Carr part no. 7056K23, $6.30 for 50]

Tools (1 per table of four kids)

Pliers (any type will do)

Wire strippers

Glue gun

Drill

5/32" drill bit

A block of wood for drilling

a drill bit the size of the width of the lighter's ignition mechanism (we use 7/32")

A large nail

Electrical tape

Crimping pliers (optional)

Calipers (optional)

Goggles

Step 1

In step 1, we will take apart the lighter and find the piezoelectric electronic ignition mechanism.

First, start with an electric lighter, like the one shown below. A flint lighter will not work for this project.

It's surprisingly easy to pull apart a lighter to get the electronic ignition mechanism. First, we twist off the thumb lever, as shown below.

Then, we pulled off the cap, as shown below.

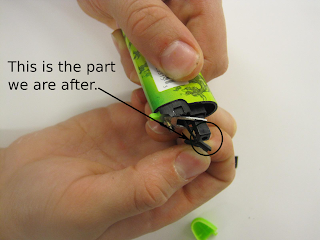

Under the cap is the piezoelectric ignition mechanism, which is shown in the photo below.

The photo below shows what it looks like when it is out of the lighter's housing.

Step 2

In step 2, we will prepare the cannon's wood base.

First, use calipers to measure the diagonal width of the ignition mechanism, as shown in the photo below. If you don't have calipers, you can estimate the size of the drill bit you'll need. A drill bit that is slightly too small is better than one that's too large.

Drill a hole in the wood base that's equal to the diameter of the small silver cylinder at the bottom of the ignition mechanism. If you are a righty, drill the hole on the bottom right side of the wood base and on the bottom left if you are a lefty. Make sure you support the wood base on a second piece of wood when you drill. Otherwise, you might ruin your counter.

For our size lighter, we used a 7/32" drill bit. The hole should be off to the side but not too close to the edge of the wood base, as shown in the photo below.

After the hole is drilled, make sure the silver cylinder at the bottom of the ignition mechanism fits inside. If the hole is too small, make it larger by rocking the drill bit around as you drill.

We also need to drill two small holes to run the two 22 AWG hookup wires through the wood base. Use your 5/32" drill bit for this. One hole needs to be near the ignition mechanism, but not so close that it will weaken the wood base. The other hole should be in the center of the wood base. The holes are shown in the photo below.

Step 3

In step 3, we will connect the wires to the lighter's ignition mechanism.

The ignition mechanism will be on the top of the wood base. The wires will connect to it and run down through the nearest hole, and then up through the center hole to the top side of the wood base. But, before we wire it, we need to figure out where to connect the wires to the ignition mechanism.

The ignition mechanism will be on the top of the wood base. The wires will connect to it and run down through the nearest hole, and then up through the center hole to the top side of the wood base. But, before we wire it, we need to figure out where to connect the wires to the ignition mechanism.

This raises a question... how does the ignition mechanism work? Before we figure that out, let's prepare the wires. We will use the two 18 AWG hookup wires to carry the electricity from the ignition mechanism to the film canister. Strip 1/4" - 1/2" off one end of both wires, as shown in the photo below. The dime is in the photo to give you a better sense of proportions.

Now back to our question of how does the ignition mechanism work? To figure that out, bend the black wire on the ignition mechanism in a loop back towards the small vertical slit in the side. Leave a small gap, about 1/8", between the slit and the end of the wire. See the photo below.

Then stand the ignition mechanism on a table, with the small silver cylinder down, and press the button on top, as shown in the photo below. DO NOT HOLD THE IGNITION MECHANISM IN YOUR HAND WHEN YOU PRESS THE BUTTON OR YOU MAY GET A HIGH VOLTAGE (I.E. UNPLEASANT) SHOCK.You should see a spark jump between the black wire and the body of the ignition mechanism. If you don't see a spark, adjust the wires. Our goal is to reroute that spark to the inside of the film canister.

Now let's connect the wires to the ignition mechanism. First, let's connect the black 22 AWG hookup wire to the black wire on the ignition mechanism. Strip 1/4" - 1/2" of insulation off the ignition mechanism wire. But before we go on, here's some sad news... the black ignition mechanism wire cannot be soldered (or at least I couldn't do it). The molecular bond to the solder simply will not form. I'd love to know why.

But alas, we can turn a lemon into lemonade and use a super cool connecting device that almost nobody ever uses anymore. It's called an insulation displacement wire connector (or a telephone tap connector because they used to use them for telephone lines before everything went digital).

Stick the stripped end of the ignition mechanism wire in one hole of the insulation displacement wire connector and stick the stripped end of the 22 AWG wire in the other hole. MAKE SURE BOTH WIRES ARE ALL THE WAY IN THE HOLES. See the photo below.

Now take your crimping pliers (or standard pliers) and compress (i.e. crimp) the orange button on the insulation displacement wire connector. Make sure the orange button is being pushed in. If you are using standard pliers, you should align the pliers so that only the sharp edge of the pliers' nose makes contact with the orange button, as shown in the photo below.

Now, we'll connect the second wire. This is a little tricky because there's only one wire coming out of the ignition mechanism. As you saw, when the ignition mechanism sparks, the sparks jumps between the black wire and the top of the vertical slit in the ignition mechanism. We're going to place the stripped end of the red 22 AWG hookup wire on top of the slit and hope that the spark will jump from the ignition mechanism to the red wire.

First, cut a 3" - 4"piece of electrical tape lengthwise, as shown in the photo below.

But alas, we can turn a lemon into lemonade and use a super cool connecting device that almost nobody ever uses anymore. It's called an insulation displacement wire connector (or a telephone tap connector because they used to use them for telephone lines before everything went digital).

Stick the stripped end of the ignition mechanism wire in one hole of the insulation displacement wire connector and stick the stripped end of the 22 AWG wire in the other hole. MAKE SURE BOTH WIRES ARE ALL THE WAY IN THE HOLES. See the photo below.

Now take your crimping pliers (or standard pliers) and compress (i.e. crimp) the orange button on the insulation displacement wire connector. Make sure the orange button is being pushed in. If you are using standard pliers, you should align the pliers so that only the sharp edge of the pliers' nose makes contact with the orange button, as shown in the photo below.

Now, we'll connect the second wire. This is a little tricky because there's only one wire coming out of the ignition mechanism. As you saw, when the ignition mechanism sparks, the sparks jumps between the black wire and the top of the vertical slit in the ignition mechanism. We're going to place the stripped end of the red 22 AWG hookup wire on top of the slit and hope that the spark will jump from the ignition mechanism to the red wire.

First, cut a 3" - 4"piece of electrical tape lengthwise, as shown in the photo below.

There are two vertical slits on the ignition mechanism. They are on opposite sides. We are going to place the red 22 AWG hookup wire on the slit that's opposite the side of the ignition mechanism where the black wires are connected. This will give us more room. Place the stripped portion of the red 22 AWG hookup wire along the vertical slit, as shown in the photo below.

Then take one of your cut peices of electrical tape and tape the insulated portion of the wire to the ignition mechanism. Do not get tape below on the silver cylinder at the bottom of the igniton mechanism. See the photo below.

Before you tape the copper portion of the red 22 AWG hookup wire in place, gently push the copper into the slip. Don't push it too far in. You can use any thin object to push it in. It should just be slightly bent, as shown in the photo below.

Now, take another piece of your cut electrical tape and wrap it around the copper on the red 22 AWG hookup wire, as shown below.

Next, you should test it to make sure there is a spark between the ends of the wire. If you haven't already done so, you should strip 1/4" - 1/2" off the ends of the two 22 AWG hookup wires. Then tape them to a table so the stripped ends are maybe 1/4" apart. If your table is a light color, it will help you see the spark if you tape another piece of electrical tape to the table under the gap between the wires. See the photo below.

Then take one of your cut peices of electrical tape and tape the insulated portion of the wire to the ignition mechanism. Do not get tape below on the silver cylinder at the bottom of the igniton mechanism. See the photo below.

Before you tape the copper portion of the red 22 AWG hookup wire in place, gently push the copper into the slip. Don't push it too far in. You can use any thin object to push it in. It should just be slightly bent, as shown in the photo below.

Now, take another piece of your cut electrical tape and wrap it around the copper on the red 22 AWG hookup wire, as shown below.

Next, you should test it to make sure there is a spark between the ends of the wire. If you haven't already done so, you should strip 1/4" - 1/2" off the ends of the two 22 AWG hookup wires. Then tape them to a table so the stripped ends are maybe 1/4" apart. If your table is a light color, it will help you see the spark if you tape another piece of electrical tape to the table under the gap between the wires. See the photo below.

Then press the button and look for the spark at the gap between the wires. If you didn't see a spark, you'll have to troubleshoot your connections.

Step 3

In step 3, we'll run the wires and finish building the cannon.

The next step is to glue everything in place.

First, glue the ignition mechanism securely in the large hole in the wooden base. If it fits snugly in the hole, you don't need to glue it. See the photo below.

Next, run the wires through the hole near the ignition mechanism, as shown below.

Then run the wires along the bottom of the wooden base and through the hole in the center of the wooden base, as shown below.

Now, you need to run the wires through the lid of your film canister. Poke a hole in the center of the lid using a nail. It may help to keep the lid on the canister when you push the nail through. Make the hole just big enough to run the wires through it, as shown in the photo below.

Then run the wires through the lid, as shown below.

The wires should stick up from the lid only about 1/2" or so. If the wires are too far up, either recut and restrip them or pull them a little bit back through the bottom of the wood base. You can glue the excess wire to the bottom of the wood base.

The wires should stick up from the lid only about 1/2" or so. If the wires are too far up, either recut and restrip them or pull them a little bit back through the bottom of the wood base. You can glue the excess wire to the bottom of the wood base.

Now, you need to bend the wires so they bow outwards and then come back together at the stripped part, where there should be a gap of about 1/4" or less. You can easily do this by putting your finger between the two wires and then bending them around your fingers, as shown in the photo below.

Glue all the wires in place and you are ready to have some fun.

Enjoy!

Firing the film canister cannon

It takes only one squirt of Binaca to fire the cannon. Spray one squirt into the film canister from about 3" away. Cap the canister on the wood base and press the igniter.

You don't need to rush to get the canister on the lid before firing. Take your time. THIS ALSO MEANS THAT YOU CAN FIRE IT WHEN YOU ARE NOT PAYING ATTENTION, SO BE CAREFUL.

ALWAYS WEAR YOUR GOGGLES WHEN FIRING THE CANNON.

No comments:

Post a Comment