This project shows how we can build an LED flashlight without batteries. The LED gets its power from kinetic energy… that is, energy from movement. When you shake the flashlight, the device will convert the kinetic energy from the shaking to electrical energy. How does it do that? Well, it relies on the principal that a magnet that passes across a wire changes the magnetic field across the wire. This change in the magnetic field generates an electromagnetic force in the wire, which causes electrons to move in the wire. And, moving electrons mean electricity!

In this project, we will take a magnet wire and wrap it at least 1400 times around a tube. We will put a small stack of cylindrical magnets in the tube and seal them inside. When we shake the tube, the stack of magnets will slide back and forth. This will create an electromagnetic force that is proportional to the rate at which the magnetic magnet field is changed. Shaking the tube more vigorously will generate a larger electromagnetic force and, therefore, more electric current and higher voltage.

In this project, we will take a magnet wire and wrap it at least 1400 times around a tube. We will put a small stack of cylindrical magnets in the tube and seal them inside. When we shake the tube, the stack of magnets will slide back and forth. This will create an electromagnetic force that is proportional to the rate at which the magnetic magnet field is changed. Shaking the tube more vigorously will generate a larger electromagnetic force and, therefore, more electric current and higher voltage.

It’s a little more complicated than that because we have three problems to solve in our project design.

- First, as the magnets reach the end of the tube, they slow down and eventually stop. This will cause our LED to blink as the magnets reach the ends of the tube. So, we need to somehow store excess electricity that is generated by the shaking and use that electricity when the magnets aren’t moving. We will use capacitors to store electricity.

- Second, the electric current will be alternating current (AC). That means that the electrons will move in one direction when the magnets move to one end of the tube, but they will move in the opposite direction when the magnets move to the opposite end of the tube. Now, we know that LEDs are Light Emitting Diodes and diodes allow electricity to flow in only one direction. So, we will need to build a super cool thing called a bridge rectifier to reroute the electrons so they flow all in one direction (DC) instead of back and forth (AC).

- Third, the voltage generated by the moving magnets may exceed the rated voltage for the LEDs. So, we'll use a voltage regulator to keep the voltage to close to our LED's voltage requirement (3.2V).

Before you begin, you may want to buy a extra acrylic tube and electrical components in case they break as you are building.

Materials

400’ 32 AWG magnet wire [McMaster-Carr part no. 7588K89, $26.29 for 4350’ spool]

1 acrylic tube, 14” long, 1" OD, 3/4" ID [McMaster-Carr part no. 8532K18, $11.09 for 6’]

1 ultra bright 10mm white LED [Leading-LEDs part no. 105PWD, $0.26 ea.]

2 Nd magnets, 11/6" dia. x 1/2" thick [Amazing Magnets part no. DB8, $4.61 ea.]

4 Schottky diodes, 1A, 20V [Jameco part no. 177949, $0.10 ea.]

2 electrolytic capacitors, 4700 UF, 16V, dia. < 3/4”) [Jameco part no. 198901, $0.69 ea.]

1 voltage regulator, low drop out (LDO), 3.3V [Jameco part no. 1323397, $0.79 ea.]

1 momentary push button switch, SPST,< 3/4" long [Jameco part no. 26623, $0.59 ea.]

Red solid core 22 AWG hookup wire, 1" long [Jameco no. 36856, $7.49 for 100’]

Black solid core 22 AWG hookup wire, 3' long [Jameco no. 36792, $7.49 for 100’]

Other color solid core 22 AWG hookup wire, 1' long [Jameco no. 36822, $7.49 for 100’]

2 zip ties, 4" long

EPDM foam tube, 1” long, 3/4" OD, 1/4" ID [McMaster-Carr no. 4339T6, $10 for 6']**

* You could substitute any material to absorb the impact of the sliding batteries, including a wad of paper towel, a cut up packing peanut or a cut up sponge.

Tools

Hacksaw

Ruler (at least 14" long) or a tape measure

Pliers

Sharpie pen

Electric drill

Drill bit, 5/16" (slightly greater diameter than the momentary switch)

Drill bit, 1/8" (diameter wide enough to thread a 4" zip tie)

Drill bit, 1/2" (or a 1/2" dia. dowel, 6" long)

Duct tape

Masking tape (at least 3/4” wide)

Lighter

Wire cutters

Wire strippers

Breadboard

1 ultra bright 10mm white LED [Leading-LEDs part no. 105PWD, $0.26 ea.]

2 Nd magnets, 11/6" dia. x 1/2" thick [Amazing Magnets part no. DB8, $4.61 ea.]

4 Schottky diodes, 1A, 20V [Jameco part no. 177949, $0.10 ea.]

2 electrolytic capacitors, 4700 UF, 16V, dia. < 3/4”) [Jameco part no. 198901, $0.69 ea.]

1 voltage regulator, low drop out (LDO), 3.3V [Jameco part no. 1323397, $0.79 ea.]

1 momentary push button switch, SPST,< 3/4" long [Jameco part no. 26623, $0.59 ea.]

Red solid core 22 AWG hookup wire, 1" long [Jameco no. 36856, $7.49 for 100’]

Black solid core 22 AWG hookup wire, 3' long [Jameco no. 36792, $7.49 for 100’]

Other color solid core 22 AWG hookup wire, 1' long [Jameco no. 36822, $7.49 for 100’]

2 zip ties, 4" long

EPDM foam tube, 1” long, 3/4" OD, 1/4" ID [McMaster-Carr no. 4339T6, $10 for 6']**

* You could substitute any material to absorb the impact of the sliding batteries, including a wad of paper towel, a cut up packing peanut or a cut up sponge.

Tools

Hacksaw

Ruler (at least 14" long) or a tape measure

Pliers

Sharpie pen

Electric drill

Drill bit, 5/16" (slightly greater diameter than the momentary switch)

Drill bit, 1/8" (diameter wide enough to thread a 4" zip tie)

Drill bit, 1/2" (or a 1/2" dia. dowel, 6" long)

Duct tape

Masking tape (at least 3/4” wide)

Lighter

Wire cutters

Wire strippers

Breadboard

Three 1.5 volt batteries (size AAA, AA, C or D)Two wire leads with alligator clips

Soldering iron

Soldering iron

Jumper wires (not necessary, but they make it a lot easier)Multimeter*

Calipers*

* optional

Calipers*

* optional

BEFORE YOU BEGIN EACH STEP, READ THE STEP THROUGH TO THE END.

Step 1

In step 1, we will prepare the tube to house the flashlight.

All the parts of the flashlight fit within an acrylic tube. We will need to cut the tube and then drill the holes for our electronics. Align the ruler's 14" mark with the end of the tube. Then, using your Sharpie, make the following marks:

Step 1

In step 1, we will prepare the tube to house the flashlight.

All the parts of the flashlight fit within an acrylic tube. We will need to cut the tube and then drill the holes for our electronics. Align the ruler's 14" mark with the end of the tube. Then, using your Sharpie, make the following marks:

- at 0", draw a long line

- at 6.5", draw a small "x"

- at 8.5", draw a small line

- at 10.5", draw a small line

- at 12.5", draw a small "x"

- at 13.25", draw a large "X".

Now, use your hacksaw to the cut the tube where you marked it with a long line. You will notice that, when sawing, it's a lot easier to pull the towards you than it is to push it away from you. So, it's a good idea to make a starting groove in the tube by using only pulling strokes. Once you have a deep enough grove, you can saw back and forth. When you saw, do not push down on the saw blade. Let gravity do the work for you.

After you have cut the tube, we need to drill a hole to hold the SPST momentary switch. Use the 9/64" drill bit to drill a pilot hole where you drew the large "X". This will help hold the drill bit in place when you make the hole larger. Then use the 5/16" drill bit to widen the hole. Make sure the hole goes through the top of the tube only. Also, don't push the drill down too hard, especially as the bit is about to break through the cylinder. Otherwise, you may crack the tube.

Now, we need to drill two holes for zip ties. I'll explain why you need zip ties later. For now, you should know that you need to use the 9/64" drill bit to drill the holes where your drew the small "x"'s on the tube. THESE HOLES NEED TO GO ALL THE WAY THROUGH THE TUBE - THAT MEANS ONCE YOU BREAK THROUGH THE TOP OF THE TUBE, KEEP DRILLING UNTIL YOU BREAK THROUGH THE BOTTOM. You need to put a board under the tube so that you don't ruin your floor when you drill through the bottom of the tube.

This is what your tube should look like when you are done.

Step 2

In step 2, we will wind our 32 AWG magnet wire around the tube.

Since we don't have a coil-winding machine, we'll have to improvise with a power drill. You could have a friend hold the spool of wire on a dowel or you could just tape the dowel to a table, as shown in the photo below. By dangling the spool as shown in the photo, you reduce the chance that a sudden lurch in the magnet wire will break the wire. If a lurch occurs, the spool will momentarily swing forward without breaking the wire. Notice how the spool dangles about 6" down from where it is taped.

Now, you need to somehow attach your tube to your drill. In the photo below, we use a 1/2 " drill bit that we have wrapped in duct tape to make it thicker. You could also use a wooden dowel with duct tape wrapped around it.

Once it is thick enough, slide the tube on the drill bit. But, make sure you feed the end of the tube that has the hole for the momentary switch (i.e. the big hole) onto the drill bit first. That way your coil will be pretty close to the drill and will be relatively stable. See the photo below.

Now stuff about 12" of wire in the end of the tube, as shown in the photo below. You'll need this extra wire later.

You are going to coil the magnet wire BETWEEN THE TWO SMALL LINES that you drew on the tube. Then, bend the magnet wire that is coming out of the tube back down the outside of the tube and use masking tape to tape it in place. It's best to put the tape just outside the space between the two lines that you drew, as shown in the photo below. This will keep the magnet wire in place as you start to coil. Make sure you don't get any masking tape between the two lines that you drew.

Now stand the drill on the floor two to three feet in front of the dangling spool. Your partner will push the drill trigger and spin the acrylic tube while you feed the magnet wire onto the tube. In order to do this, you will have to do the following:

- POSITION YOURSELF COMFORTABLY

- USE YOUR DOMINANT HAND TO HOLD THE MAGNET WIRE AS THE TUBE SPINS

- ANCHOR YOUR ELBOW ON THE GROUND OR YOUR LAP SO THAT YOU CAN KEEP YOUR HABD EXTREMELY STEADY AS THE ACRYLIC TUBE SPINS. (You can even lie on the ground and anchor your elbow on the floor or some books.)

- PINCH THE MAGNET WIRE LOOSELY

- YOUR PINCHED FINGERS SHOULD TOUCH OR ALMOST TOUCH THE SPINNING TUBE (AS SHOWN IN THE PHOTO BELOW)

At first, spin the tube as slowly as possible. Once you see that things are going well, speed up but never go to fast. One mistake an you'll have to start over. Make the coils as tight as possible (as shown in the photo below), but if your fingers hurt from pinching the magnet wire, you are pinching too hard.

Slowly move the line back and forth. Move it very slowly so the coils are right next to each other. Wrap the magnet wire along the tube, up to the second line that you drew. This should be 2" from where you started. TRY NOT TO GO PAST THE 2" MARK.

The coils will get messier as you go. Don't worry about it, but just make sure you don't move back and worth along the coil too quickly. You should spin dozens of coils each time you go down the tube. You are trying to coil the magnet wire around the tube at least 1400 times, but it's too hard to count the number of coils. We're going to measure the thickness of the coiled to estimate when we have coiled it enough.

Any time you stop coiling, PUT A PIECE OF MASKING TAPE ON THE END OF THE WIRE THAT RUNS TO THE SPOOL, AS SHOWN IN THE PHOTO BELOW. If you don't do this, you run the risk that the magnet wire will uncoil.

When you think you are done, PUT A PIECE OF MASKING TAPE ON THE COIL TO KEEP IT IN PLACE and then use a set of calipers to measure the diameter of your coils. If you don't have calipers, you can use a ruler. The coils should be at least 1.25" (32mm) thick.

Another way to check whether you have made enough coils is to check its impedance with a multimeter. You don't need to do this if you measured the coils, but it's fun to use a multimeter. If you don't want to measure impedance, skip down in these instructions to the paragraph that starts with "Once you are sure you have enough coils....".

To measure the impedance, you will need to burn the enamel coating off the magnet wire and connect your wire leads with alligator clips to the exposed copper underneath the enamel. The photo below shows how to burn the enamel off. Don't burn the magnet wire too long or you will weaken it.

Now burn an inch or so of the magnet wire that is leading to the spool. Don't burn it too close to your coils. You need a foot or two of wire between your coils and the burned area. If your coils fail the impedance test, you will need to keep coiling. After you have burned the two ends of the wire, clip the test leads to the exposed copper as shown in the photo below.

Set your multimeter to measure Ohms (Ω) and set the dial to measure the lowest number of Ohms (200Ω in the photo above). As you can see, in the photo above, the impedance measured 151.1, which was sufficient.

Once you are sure you have enough coils:

- clip the magnet wire that leads to the spool. Make sure you have a foot of extra magnet wire after your coils

- burn the enamel off the newly clipped end

- put a big piece of tape on the coil (to replace your small piece), as shown in the photo below.

Step 3

In step 3, will will insert the magnets and seal them inside the acrylic tube.

In step 3, will will insert the magnets and seal them inside the acrylic tube.

Insert a zip tie in one of the small holes that you drilled in the tube. Then cut about 1/2" of the EPDM foam tube, as shown below. If you don't have EPDM foam, you can use anything to cushion the magnets when they hit the zip ties. Even a small wad of paper towel should work.

Then insert the cut piece of EPDM foam into the acrylic tube. It should be on the same side of the zip tie as the coils of magnet wire. See photo below.

Now, insert the magnets so they slide inside the magnet wire coils. Then cut another 1/2" of EPDM foam and insert it in the tube and then seal it with the second zip tie. When you are done, it should like the tube in the photo below. (You can't see the magnets but they are inside the magnet wire coils.)

Step 4

In step 4, we will build the circuitry.

Whenever you plan to solder a circuit together, it makes sense to lay it out on a breadboard first. That way you can be sure the circuit works before you solder it and make it permanent.

First, lay out the parts of your circuit, as shown in the photo below.

In step 4, we will build the circuitry.

Whenever you plan to solder a circuit together, it makes sense to lay it out on a breadboard first. That way you can be sure the circuit works before you solder it and make it permanent.

First, lay out the parts of your circuit, as shown in the photo below.

In order to build the circuit, you'll have to know how a breadboard is wired internally. If you are unfamiliar with breadboards, read this article on Using the Breadboard. You only need to read up to the section "About Jump Wires".

Once you know how to use a breadboard, let's build the bridge rectifier. The purpose of the bridge rectifier is explained in here.

Put your diodes in the breadboard to match the diodes in the photo below. Diodes have polarity, which means they have a negative and positive side. The negative side is the cathode and the positive is the anode. The cathode is the side that has the little gray stripe. Pay close attention to the direction that the stripe faces.

If the diode's lead bends when you push it into the breadboard holes, you can use needle nose pliers to feed it into the hole, as shown below.

Arrange the four diodes as shown below.

Our bridge rectifier is complete. Before we go on, you should understand the bridge rectifier better. To give our circuit power, we will connect our two magnet wires to it in the spots indicated below.

And the power will come out of the bridge rectifier in two spots just like on a battery... one for positive and one for negative.

Now that we know where to connect our positive and negative wires, we can continue to build our circuit. Let's add some capacitors to store the electricity that flows from the bridge rectifier.

Like diodes, capacitors have polarity (i.e. a positive and negative connection). If you look at the two leads running from the capacitor, one is shorter than the other. The short lead is always the cathode. You'll also see a big minus sign printed on the side of the capacitor.

We need to connect the capacitor's anode to the positive connection of the bridge rectifier and the cathode to the negative connection of the bridge rectifier. Let's plan on putting one capacitor in column 25 of the breadboard and the second in column 30. We'll run the wires to those columns before we insert the capacitors so you will be able to see what's going on.

Starting with negative, we run the red jumper wire shown in the photo below.

Now, let's run the positive by inserting the white jumper wire shown in the photo below.

That's it for column 25 of the breadboard. Now let's wire the capacitor that goes in column 30. The green jumper wire below connects the negative wire to column 30.

The top green wire below connects the positive wire to column 30.

Now lets connect the capacitors. Make sure their cathodes are connected to negative (i.e. the bottom section of the breadboard, rows F - J).

Add the second capacitor.

Now, let's add the voltage regulator to columns 40 - 43. First, we need to run jumper wires to the voltage regulator. Let's start by running the brown jumper wire shown below, which runs from the anode of the second capacitor.

The voltage regulator has three pins. When you hold the flat side of the voltage regulator towards you, they are numbered 1 to 3, from left to right.

Pin 1 is the positive connection for the part of the circuit where the voltage is unregulated (i.e. the part of the circuit where the bridge rectifier and the capacitors are). Pin 3 is the positive connection for the part of the circuit where the voltage is regulated by the voltage regulator (i.e. the part of the circuit where the switch and the LED are). And, pin 2 is the negative connection for both parts of the circuit.

So let's connect the voltage regulator. Pin 1 should connect to the anodes of the capacitors (positive), as shown below.

Now, let's run a jumper wire from the cathode of the second capacitor to pin 2 of the voltage regulator, which is the red wire below.

No let's connect the SPST momentary push button switch to the breadboard. Your switch has solder lugs, so you won't be able to connect it to the breadboard unless you solder some wires onto it. So, let's do that. Use your solid core 22 AWG hookup wire. Make one of the wires relatively long (at least 2'). The other wire can be much shorter, 2" - 3". Then strip about 1/4" of the ends of both wires, as shown below.

Now, take the long solid core 22 AWG hookup wire and use your pliers to bend the stripped portion in the middle, as shown below.

Insert the stripped end into the solder lug and bend the stripped portion tightly around the solder lug, using pliers if you need to. (See below.)

Solder the connection. Now, take the sort solid core 22 AWG hookup wire and bend the stripped portion just as you did the long wire, as shown below.

When both wires are soldered, the should look like those in the photo below.

Crumple the long wire together so it doesn't get in your way, as shown below.

Now, let's connect the SPST momentary push button switch to the breadboard. Let's connect the switch's short wire to the negative lead of the voltage regulator, pin 2. (You could just as easily attach it to the positive lead, pin 3.) Let's connect the switch's long wire some distance away, as shown below.

The next step is to insert the LED. The cathode is the shorter lead, as shown below.

The cathode connects to negative, so we'll need to connect it to the long wire of the SPST momentary push button switch, as shown below.

To complete the circuit, we need to run a jumper wire from the LED's anode to the positive lead of the voltage regulator, pin 3. This is the brown wire that runs from the LED in the photo below.

Both the unregulated and regulated part of the circuits are now complete. Let's hook it up to some batteries to see if it works. First, we need to connect some jumper wires to the part of the bridge rectifier where the magnet wires go. These are the two gray wires on the left side of the breadboard in the photo below.

Let's hook up some leads with alligator clips to the two jumper wires, as shown below.

We'll need at least three batteries (4.5V) to test the circuit. Put the batteries in series (i.e. the positive terminal of one connects to the negative terminal of another). Get a friend's help to hold the alligator clips against the positive and negative terminals of the two outside batteries.

Then push the button on the SPST momentary push button switch. The LED should light up. If it doesn't, you'll need to troubleshoot your circuit.

Step 5

In step 5, we will make the circuit permanent by soldering the components together. Let's start by cutting the wire we'll need to replace our jumper wires. This is what you'll need:

Step 5

In step 5, we will make the circuit permanent by soldering the components together. Let's start by cutting the wire we'll need to replace our jumper wires. This is what you'll need:

- two 14" pieces of green solid core 22 AWG hookup wire. (If you don't have green, use any color other than red or black.)

- four 3" pieces of red solid core 22 AWG hookup wire

- three 3" pieces of black solid core 22 AWG hookup wire

- one 18" piece of red solid core 22 AWG hookup wire

Strip about 1/2" off the end of each of the wires above. We'll build the permanent circuit in two steps:

- First, we will solder leads onto our components.

- Second, we will solder the components to each other.

Let's solder the bridge rectifier first. We need to solder the diodes together and then attach a wire lead to each of the bridge rectifier's four corners. The hot below shows what the bridge rectifier looks like before we begin.

Let's start with the left and top diodes.

- Pull them off the breadboard and twist together the leads that were connected by the breadboard.

- Then wrap one of the stripped 14" green solid core 22 AWG hookup wires around it, as shown in the photo below.

If you have a hard time twisting the wires together, you can use pliers as shown in the photo below.

Solder the twisted wire and leads together, as shown in the photo below.

Repeat the process for the other two diodes, using a second 14" green solid core AWG hookup wire.

Now, twist the cathodes and anodes together.

Let's connect negative and positive wires to the diodes and solder the connections.

Let's start with the negative wire (the 3" black solid core 22 AWG hookup wire). The negative wire connects to the diodes that have their anodes twisted together (i.e. the black end facing the untwisted lead), as shown in the photo below.

Next, let's connect the positive wire (the 3" red solid core 22 AWG hookup wire). This wire connects to the diodes that have their cathodes twisted together (i.e. the side with the gray stripe facing the untwisted lead), as shown on the photo below.

This is what it the bridge rectifier should look like. Check the direction of the gray stripes to make sure they match those in the photo below.

Now let's move on to the voltage regulator. Let's start by soldering a 3" solid core 22 AWG hookup wire onto each of the leads. You will use two red wires and one black wire, as shown in the photo below.

Use your Helping Hands. Also, if you clip the alligator clip onto the wire's insulation instead of clipping it to the metal wire, the alligator clip won't absorb your soldering gun's heat. See the photo below.

If you have trouble keeping the wire and the lead next to each other, try putting both of them in the jaws of the alligator clip, as shown below.

Solder all three wires in place.

Mark the pin 1 and pin 3 wires so you can tell them apart after you put electrical tape on the voltage regulator.

Now, let's connect negative and positive wires to the capacitors. You'll need a 3" red solid core 22 AWG hookup wire and 3" black solid core 22 AWG hookup wire.

First, let's connect positive (red). Twist the stripped end of the 3" red wire around the two anodes of the capacitors.

All three wires should be soldered together, as shown below.

Now, solder the negative (black) wire to the capacitors' cathodes, as shown below.

The finished product is shown below.

Here are all three components with their properly colored leads attached.

Now, we need to put electrical tape around the connections so they don't short circuit. First, tape the voltage regulator.

Two pins are taped.... (By the way, you don't need to tape the pin 2 lead if the pin 1 and pin 3 leads are taped well.)

All three leads are taped.

After the three leads are taped, pinch them together, as shown below.

And, wrap a piece of electrical tape several times around the three small pieces. This should prevent the voltage regulator's fragile pins from breaking off.

The photo below shows what it should look like when you are done.

Now, put electrical tape on the bridge rectifier's soldered connections. When you are done, it should look something like the photo below.

Next, tape one of the soldered connections of the capacitors, as shown below.

Next, we will solder together (1) the red wire on the bridge rectifier, (2) the red wire on pin one of the voltage regulator, and (3) the red wire on the capacitors. Lay the components out on a table and twist the three red wires together, as shown below.

Use your Helping Hands to solder the wires.

Now, will will solder together (1) the black wire on the bridge rectifier, (2) the black wire on pin 2 of the voltage regulator and (3) the black wire on the capacitors, as shown below.

This is what the components should look like when you are finished.

Tape the connection of the three red wires, but not the connection of the three black wires. Now, we will solder the 18" red solid core 22 AWG hookup wire to the LED's anode (positive), as shown below.

Now, tape the soldered connection.

When you are done with the flashlight, the LED and the momentary pushbutton switch will be in the front of the flashlight and the components will be in the back. So, the wires from the LED and the momentary pushbutton switch will run from the front of the flashlight to the back. Let's make sure that the wires aren't too long.

First, put your circuit inside the long end of the tube. Start with the capacitors, as shown below.

Then, slide the voltage regulator in the tube.

Before you slide the diodes in, you need to get them closer together so they fit. The easiest way to do this is by pulling two opposite sets of diodes away from each other.

This will move the other two sets of diodes towards each other.

Bend the diodes' taped connections towards the capacitors.

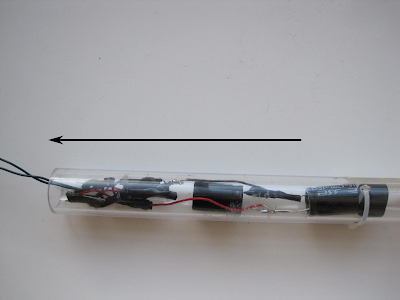

Slide them into the tube. All the components should fit in the tube.

Now, loosely place the momentary push button switch in the other end of the tube, where it will eventually be screwed in, as shown below.

Then, run the long black wire down the tube as shown below. You should trim it at the left capacitor, shown by the dotted line in the photo below. After trimming, it should be about 18" long.

Next, we will measure and trim the red wire that runs from the LED. Take the push button switch out of the tube and replace it with the LED, as shown below.

Now run the long red wire down the tube and trim it just as you did the black wire., as shown in the photo below.

Once you have trimmed your long black and long red wires, you can solder them. First, gently pull your circuit out of the tube.

Let's start by soldering the long black wire that connects to the momentary pushbutton switch to the soldered three black wires in your circuit. Wrap the stripped end of the long black wire around the soldered joint of the three 3" black wires. Then solder the long wire to the other three, as shown below.

snf

sadnflasnd

smadnlfnasldn

samdlfknasdl

asndl'ansd

Then tape the connection, as shown below.

Now, let's solder the momentary pushbutton switch's short black wire to the LED's cathode (negative).

Next, solder the LED's long red wire to the red wire connected to pin 3 of the voltage regulator.

d

Thanx so much for the post!

ReplyDeleteAre these the complete steps?

I was looking into making a wall lamp... would there be possible to modify the way you make the magnets move? (say pump instead of shaking?)

THNX!

Synthesis India - Transformer Winding Machines, Coil Winding Machines comprises of various Automatic Winding Machines that are specifically designed to cater to the winding needs of various Sectors like auto component, Electrical and Electronics, white goods, etc. in India.

ReplyDeleteCool project

ReplyDelete